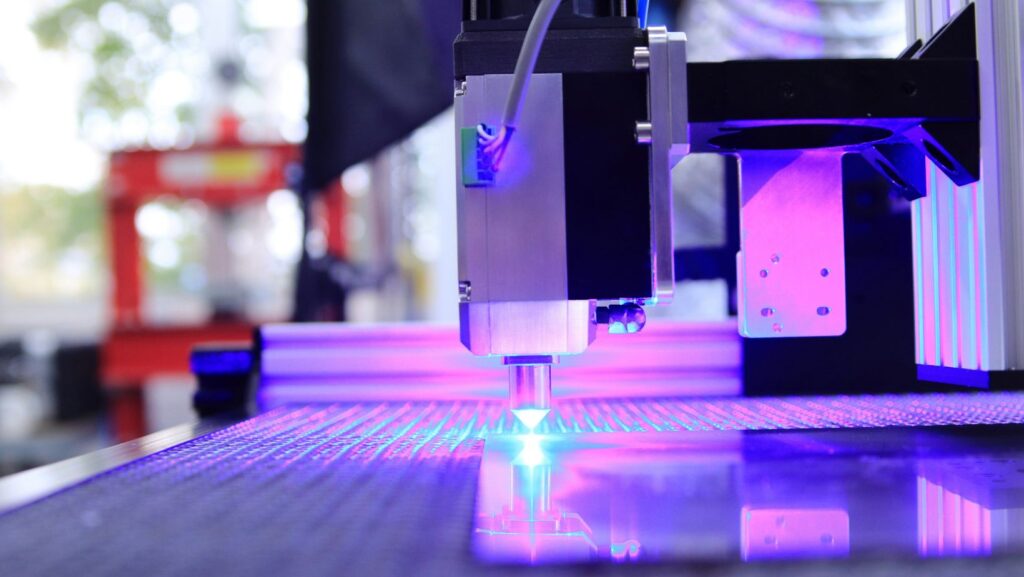

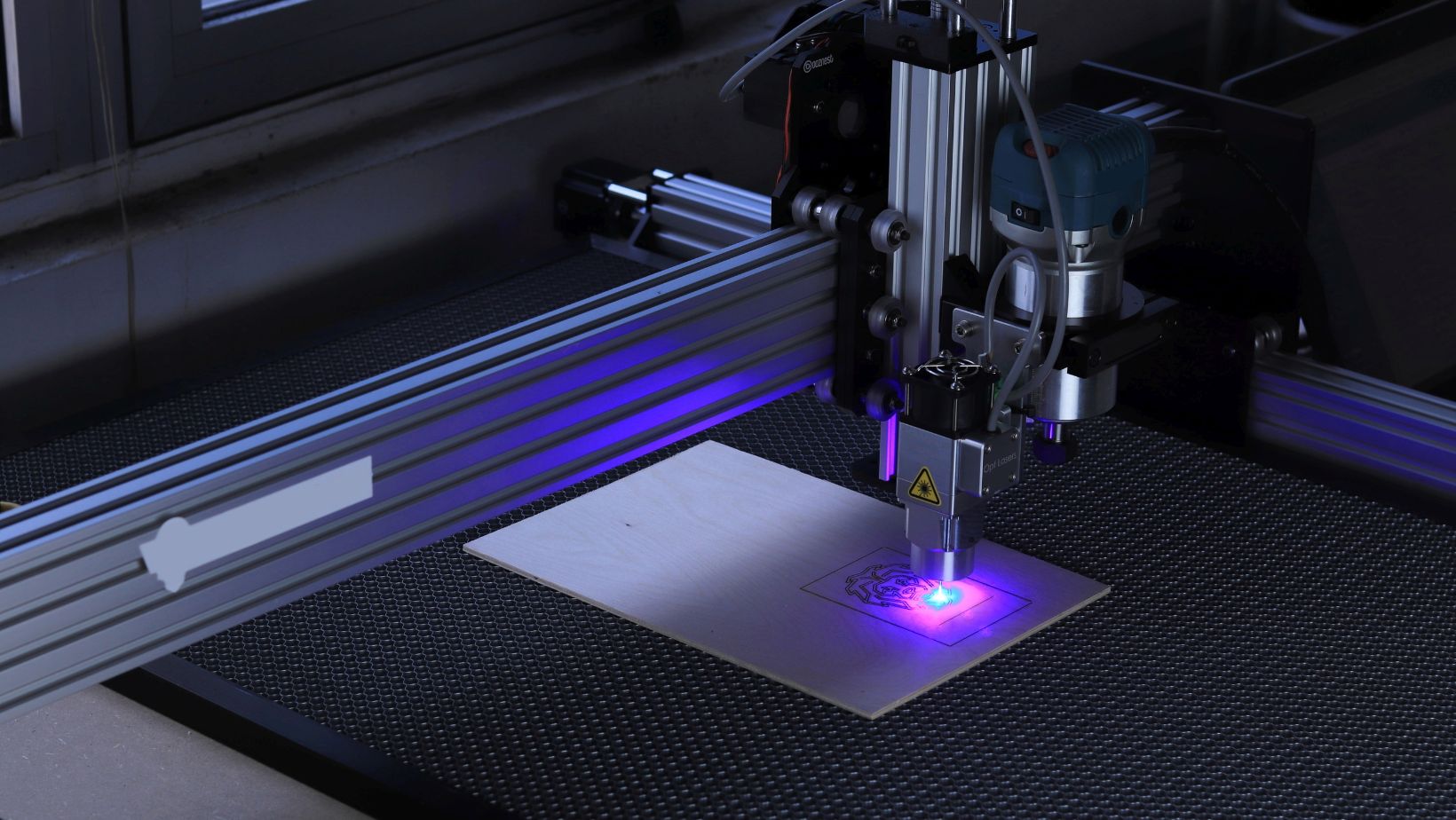

The world of crafting and design has been profoundly transformed by laser-cutting technology, enabling the translation of digital concepts into physical objects with extraordinary precision. Central to this revolution are laser-cut files, the digital blueprints that instruct laser machines to cut, engrave, and score a vast array of materials. Whether you’re a seasoned maker, a burgeoning entrepreneur, or a hobbyist eager to explore new creative avenues, a thorough understanding of these versatile files is paramount to harnessing the full capabilities of a machine. For those seeking high-quality, ready-to-use designs, exploring extensive collections of laser cut files can provide an invaluable head start for any project.

Laser Files: Machine’s Language

At its essence, a laser cut file is a digital design that provides precise instructions for a laser cutting machine. Unlike conventional images composed of pixels, which define a fixed grid of color information, they are typically in vector format. This means they’re constructed from mathematical paths, points, and curves, giving them inherent scalability and precision that pixel-based images simply cannot match. This fundamental difference is crucial for how the laser interacts with your material.

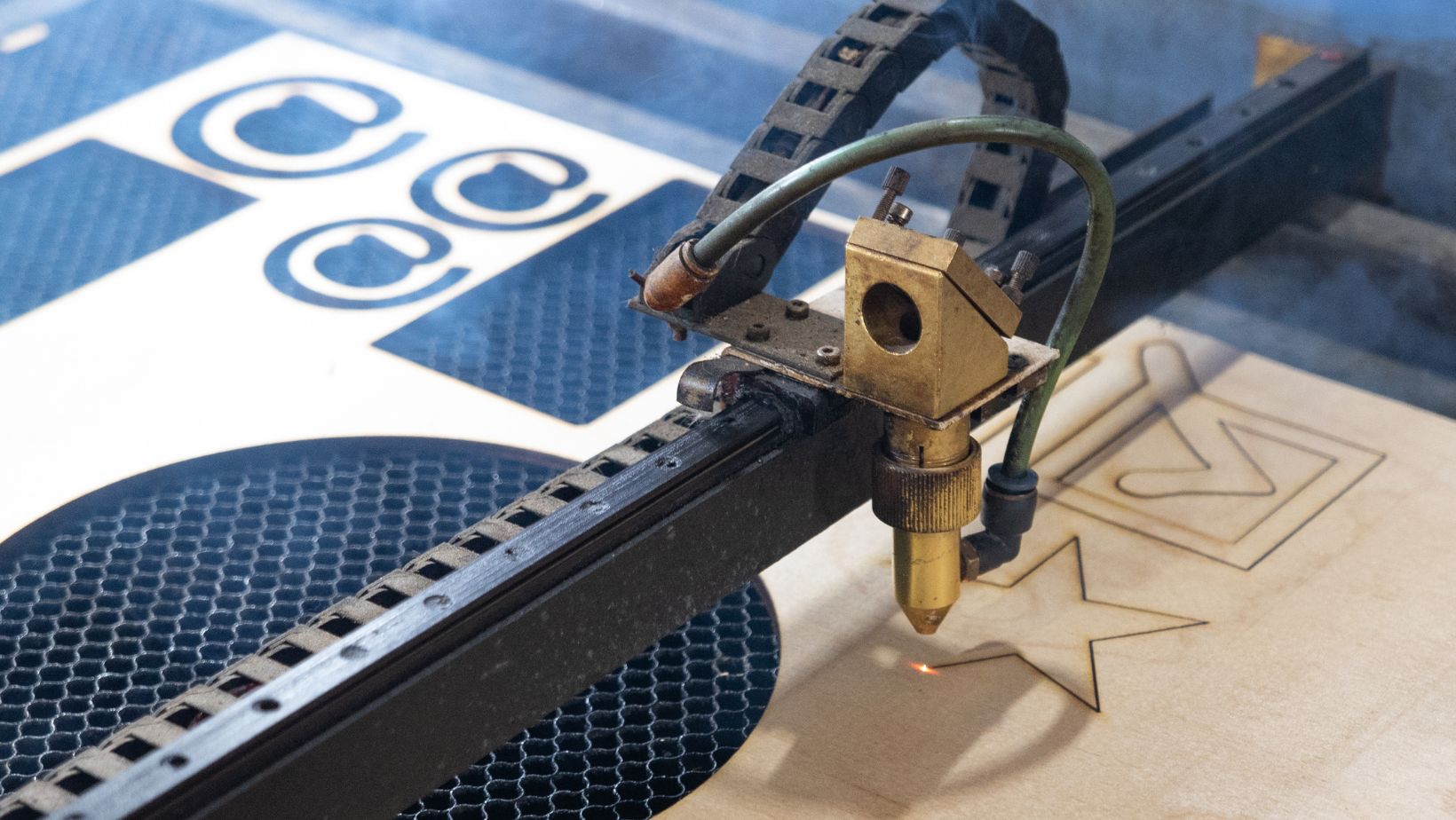

Vector paths are the actual lines and shapes the laser will follow to perform a cut or a score. Each segment of a line is mathematically defined, allowing it to move along these paths with extreme accuracy. Common vector file formats suited for cutting include SVG, DXF, AI, and EPS. While the primary function of laser cutters is to follow these vector paths, they can also engrave raster images. In this process, the laser moves back and forth, burning tiny dots onto the material surface to create a shaded effect, akin to how an inkjet printer creates an image. Formats like JPEG, PNG, and BMP are typically used for this engraving application.

Why Laser Files Are a Game-Changer

The widespread adoption of accessible laser-cutting technology, driven by the sophistication of these digital files, has dramatically expanded the horizons for creators across various disciplines. The benefits are multifaceted, offering advantages in precision, material versatility, and operational efficiency.

One of the most compelling advantages of using cut files is the incredible precision and intricate detail they enable. Laser cutters can achieve tolerances down to a fraction of a millimeter, allowing you to create extraordinarily detailed patterns, delicate lace-like structures, or complex interlocking components that would be either impossible or prohibitively time-consuming to produce by hand. Plus, once a design is meticulously perfected within a laser-cut file, it can be replicated identically countless times. This ensures remarkable consistency, which is vital for production runs or for creating multiple identical items. Lilian Barker, a prominent designer at The Makewell Paper Co., succinctly articulates this crucial relationship: “Laser cut files are more than just pretty designs; they are precise instructions. The cleaner your file, the cleaner your cut. It’s about translating creativity into perfectly executed lines and shapes.” Her insight underscores the direct correlation between the quality of your digital file and the perfection of your physical outcome.

Beyond precision, these files empower versatility across a vast spectrum of materials. Laser cutters, guided by the precise instructions within the file, can work with an astonishing array of substances. This includes various types of wood (plywood, MDF, balsa, hardwoods), acrylics (transparent or colored plastics), paper and cardboard for intricate invitations or prototypes, and even softer materials like leather, fabric, and felt. The remarkable ability to apply the same design file to different materials—simply by adjusting the laser’s power and speed settings—provides immense creative and production flexibility.

Finally, laser cutting driven by digital files offers significant efficiency and speed. Compared to manual cutting or many traditional manufacturing methods, the process is incredibly streamlined. This translates to rapid prototyping, allowing you to quickly test and refine new ideas. It also facilitates efficient batch production, enabling the creation of numerous identical items with minimal effort once the file and machine settings are optimized. Moreover, the precision of laser cutting often leads to reduced material waste, particularly when designs are cleverly “nested” to fit together efficiently.

Essential Tips for Perfect Cuts

To ensure a seamless workflow and consistently successful projects, makers must be aware of several important technical considerations when either creating or acquiring laser-cut files. Adhering to these guidelines can prevent common pitfalls and optimize your output.

First, file format compatibility is paramount. It’s essential to verify which file formats your specific laser cutter’s software supports. While SVG and DXF are widely recognized and highly compatible across various platforms and machines, making them excellent general choices, professional design software often uses AI and EPS formats. Understanding these distinctions is crucial for smooth integration between your design software and your cutter.

Another critical aspect is the proper definition of line thickness and avoiding overlapping paths. For cutting operations, lines within your design software should typically be set to a “hairline” thickness. This signals to the cutter that the path is intended for a single cut. Overlapping lines, where the laser might attempt to cut the same path multiple times, can lead to issues such as excessive burning of the material or unnecessary processing time. A well-prepared file will feature clean, distinct, and single-line paths for cutting.

Furthermore, kerf compensation is an important concept for precise designs. “Kerf” refers to the minute amount of material that the beam vaporizes or melts away during the cutting process. For projects requiring tight fits, such as interlocking pieces, you might need to subtly adjust the dimensions within your vector files to account for this material removal, ensuring that components fit together snugly as intended.

Finally, while the digital file provides the design, the actual execution relies heavily on the material settings configured on the laser cutter itself. The power, speed, and focus settings are critically important for achieving the desired cut, score, or engraving effect on a specific material. These settings are highly dependent on both the machine model and the type and thickness of the material being used, often necessitating preliminary test cuts to dial in the optimal parameters.

Ready to Create?

Laser-cut files are the bridge between your digital creativity and tangible results. They empower you to produce precise, intricate, and repeatable designs across a multitude of materials. By understanding the fundamentals of these files, their vector nature, and the critical considerations for effective use, you can harness the incredible power of laser cutting. Dive into the world of digital designs, explore the vast resources available, and confidently begin transforming your innovative ideas into physical realities with unmatched precision and ease.